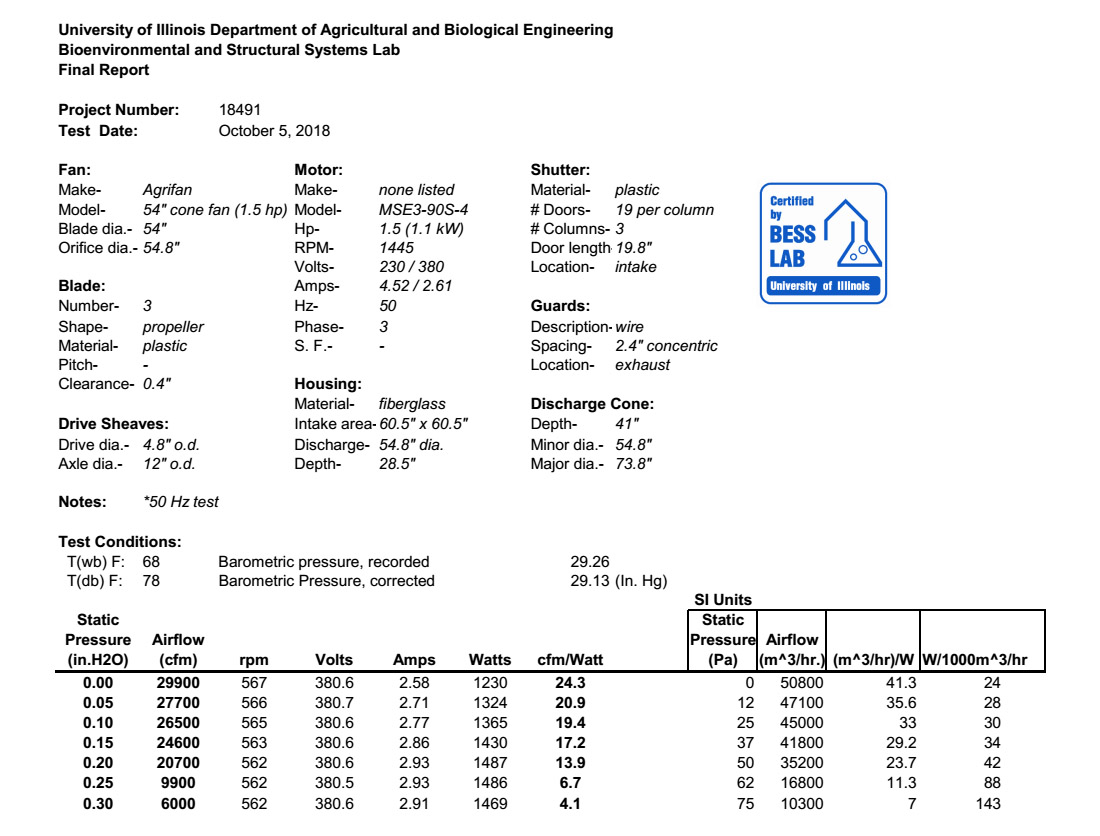

Each test included here is for a "fully dressed" fan with shutters and screens attached and mounted as normally installed.

一、Fan Selection Criteria

Select Fans Matched to Your Requirements:

1.Quantity of air delivered at different static pressures

2.Energy efficiency

3.Quality of dealer service and support

4.Reliability and life

5.Suitability for application

6.Cost - Purchase

7.Cost - OperatingThe quantity of air delivery and energy efficiency, measured and reported in these tests, are particularly important criteria in selecting fans.

二、Select Fans to Meet Airflow Requirements

The air delivery at 0.10 inches static pressure is especially important because it is the typical pressure a fan operates against in livestock buildings. Performance data for fans are often reported for 0 inches static pressure (free air), a situation rarely encountered in practical applications. Design guides such as The Midwest Plan Service Swine Handbook and Dairy Handbook provide recommended ventilation rates for cold, mild and warm weather. Fans should be selected so that these requirements can be met .

A flat performance curve, or an "Airflow Ratio" approaching one, is desirable for cold weather fans in livestock buildings. The "Airflow Ratio" is the ratio of a fan's airflow at 0.2" S.P. divided by it's airflow at 0.05" S.P.. Wind can cause the pressure across the fan to vary over this range.

Energy efficiency for summer and mild weather fans is particularly important. More air is moved at these times and energy efficiency is an important cost factor.In some applications higher operating pressures are important. When the fan must pull or push air through evaporative pads, poultry light traps or long collection ducts, operating pressures of 0.25" S.P. or above are possible.

三、Consider Energy Efficiency when selecting fans

Efficiencies of commercially available fans typically vary by a factor of 2. Annual cost of operating the most efficient 36" fans for 120 days at $0.10 kWh electricity rate, is about $150 compared to about $300 for the most inefficient fan. This translates to $1500 difference in electricity costs over 10 years.

四、Cleaning and Maintenance

Maintenance practices have a major effect on fan performance. Clean fan blades, shutters and guards regularly. In one documented case, cleaning the shutter and guard increased fan performance almost 40%. On belt driven fans check the belt for wear and correct belt tension.

CHINESE

CHINESE